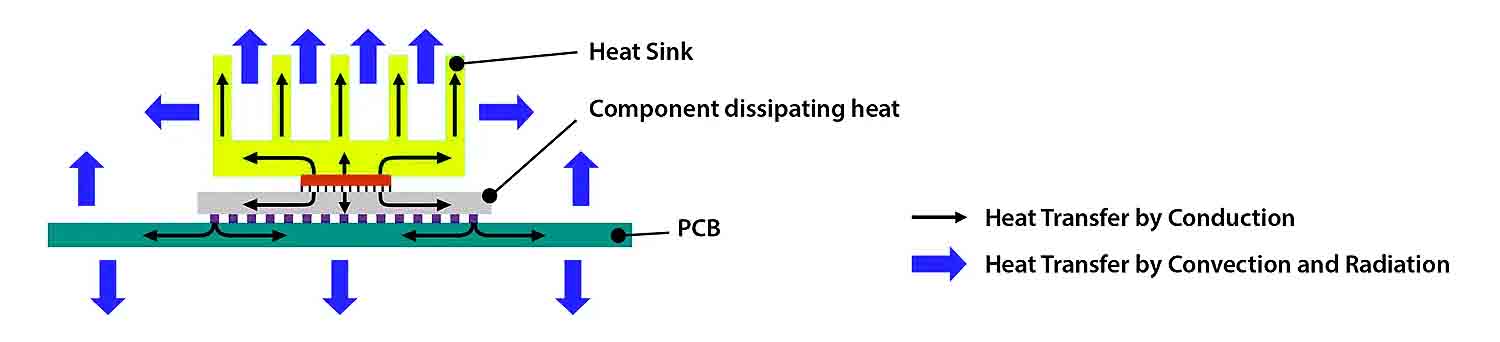

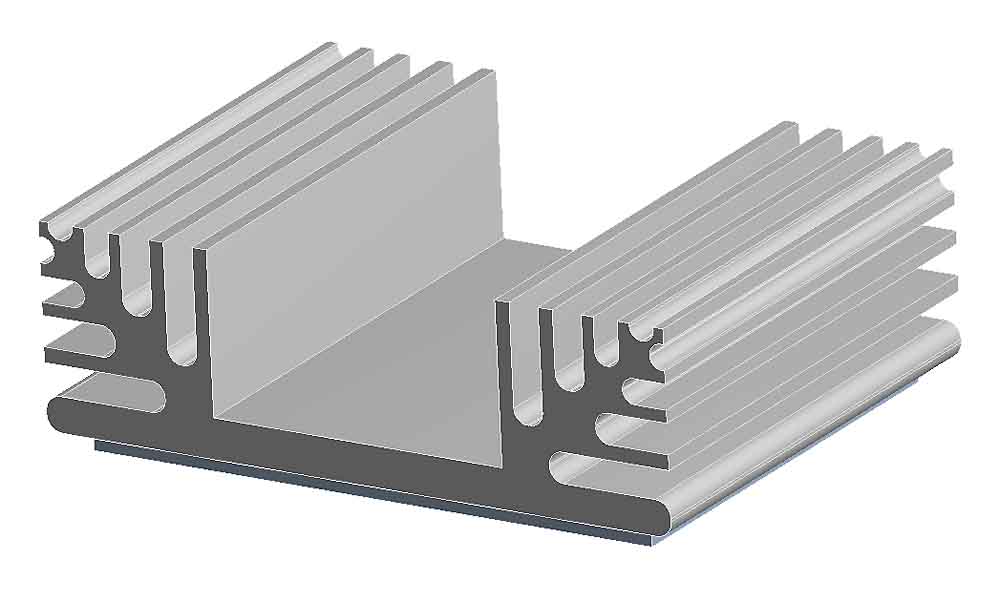

Thermal Management and Design of Heat Sinks

Estimated Reading Time: 6 minutes

Estimated Reading Time: 6 minutes