Abstract

In this article we reviewed various resin types in 3D printing, their advantages and disadvantages, and the factors to consider when choosing them.

By Maryam Vanaee, Cademix Institute of Technology

What Is Resin 3D Printer?

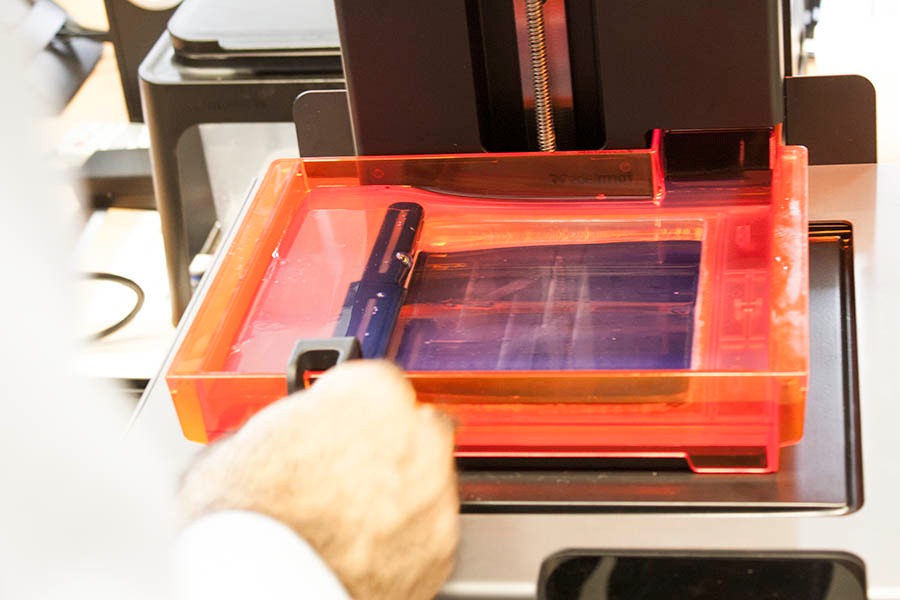

Resin 3D Printer is a liquid polymer material that is converted from its aqueous state to a solid shape in 3D printing via a series of reactions. Resin 3D printers are available for stereolithography (SLA) Laser 3D printing, LCD/MSLA 3D printing, and digital light processing (DLP) 3D printing. There is a wide variety of resin materials that provide high-quality and highly detailed, smooth result. When it comes to 3D printing, there are several methods for creating new products. Each of these methods makes use of one-of-a-kind raw materials designed specifically for this purpose. Resin is one of the most commonly used raw materials in 3D printing.

Different Technology Of Resin 3D Printer

The technology used by resin printers is stereolithography (SLA) along with digital light processing (DLP). This technology uses UV light source for liquid resin conversion into a solid; while other printers deposit molten plastic with a hot nozzle.

What To Consider When Selecting A Resin 3D Printer

When it comes to selecting resin for your 3D printing needs, you must consider several factors along two broad lines: materials and application. When it comes to materials, the following factors should be at the top of your priority list.

- Elongation

- Tensile Strength

- Water Absorption

- Quality of Finish

- Durability

- Transparency

- Costs

Advantageous And Disadvantageous Of Using Resin

There is no underestimating the impact that 3D printing has already had on the manufacturing industry, and more is still to come as advancements continue. Resins play an important role in this expansion; the following are the advantages and disadvantages of using resins for 3D printing.

Advantageous

- Resin-based prints have higher resolutions and appear much better and more detailed than any other raw material used in 3D printing. The laser technology used in the process is precise, reproducing a model with very small margins of error.

- When we use resins instead of filaments, the printing process is much faster. The extruder in the FDM system must move around the print bed to drop the aqueous filament, which takes too long. In resin-based printers, the laser does all of the work while curing and hardening the product at the same time.

- Resin-based products are more durable, robust, and visually appealing than FDM-based products. The resin-treating method makes the products more robust because this method reinforce each time a layer is laid down. In a nutshell, you don’t have to wait for the product to be ready before beginning the hardening process; by the time the product is finished, all of the treatment processes have been completed.

Disadvantageous

- Resins are expensive, which is unsurprising. Because of their efficiency, it goes without saying that the cost of producing them is also high, as they require high-quality raw materials and complex processes. An FDM 3D printer costs around $300, whereas the cheapest resin 3D printer currently costs more than $1000, with many exceeding $3000. Resin liquid is also expensive and not widely available.

- Resins are not as malleable as the end products. Resin printing done from a single type of resin without mixing it with another; this is the only way to ensure uniformity. This is good for quality, but it limits the number of ways a person can design and get the most out of their 3D printer.

- Resin he post-processing aspect of dealing with resins is somewhat complicated and, for the best results, necessitates the services of a professional. The support structures must be carefully removed, sand polished, and painted so that they do not interfere with the original surface of the product. For a beginner, this can be time-consuming, and they are more likely to make mistakes if they do it alone.

- It is extremely dangerous to handle resin without gloves. The entire procedure should be carried out in a well-ventilated room, and you must wear a mask at all times. The chemicals used in the manufacture of resins are known to interfere with the nervous system if exposed to them for an extended period of time.

- The availability of resin-based 3D printers, as well as the resin itself, is limited. Due to their high cost, few stores stock them. When compared to FDM-based printers, they rarely leave the shelves. The community of people who use resins is too small, which has hampered product distribution. Things will change as they become less expensive in the future.

Types of Resin

With today’s technology, there are approximately five different types of 3D Printing resins in use. We can use each resin 3D printer to produce a different type of product. The five are as follows.

Standard resins

This is the type of resin with a smooth surface finish that is free of bumps and scratches. It provides excellent quality at very low prices. people who looking for a low-cost resin material for mass production can use them. The resin is available for both products that require support and those that do not, with any extra protrusion easily removed using tools such as sanding paper. Standard resin products have a high level of detail, are translucent in nature, smooth to the touch, and easy to paint over in post-processing.

Clear Resins

Another popular option for those looking to make transparent 3D prints is clear resin. It belongs in the same category as Standard Resin, but it deserves its own because of the unique color. Many resins are available in clear colours such as clear red, clear green, clear blue, and simply clear.

Tough Resins

Tough Resin is the ideal material for creating strong, functional resin 3D prints that can withstand stress and strain. We also know it as ABS-like because its mechanical properties are similar to those of ABS. This material is ideal for manufacturing mechanical parts such as machine assembly components, wearable items, and other items that must withstand wear and tear.

Flexible Resins

Flexible Resin is a one-of-a-kind material with rubber-like properties. It enables users to create firm parts with a high degree of flexibility, though the latter is dependent on the resin’s specific Shore Hardness value. It can easily withstand bends and compressions and is ideal for packaging materials, handles, grips, gaskets, and stamps.

Water-Washable Resins

Water-Washable Resin is exactly what it sounds like. This material distinguishes itself through simple and easy post-processing with water rather than IPA (Isopropyl Alcohol) or anything similar. Aside from its simplicity, this resin has a lower odour and a higher strength than Standard Resin. It is, however, quite brittle as a result of the gradual water absorption by the part as you clean and post-process it with water.

About the Author

Maryam Vanaee with a Master’s degree in chemistry, graduated in 2017 and immediately entered the related job market. She has work experience as a director of research and development at a private chemical company. Her first article is about pectin extraction review . Other article is superabsorbent polymer review . She is also a member of Cademix Career Autopilot program – the acceleration program, and open to new opportunities. Please feel free to contact her:

WhatsApp:+98 937 908 0089

Email address: maryam1370.vanaee@gmail.com

LinkdIn account: maryam.vanaee

Keywords related to Resin 3D printer

Additive, Additive manufacturing, Fabrication, Rapid-prototyping, 3d print, To print, Three-dimensional, Printed parts, prototyping, Mechanical properties, materials, Printing technologies, Plastics, Photopolymer, UV, polymerization, polymerization, Stl, STL printing, polymer, resins, UV stop, Photo polymerization, Stereolithography, Photopolymer, UV, polymerization, STL printing, polymer, resins, UV stop, Photo polymerization, printing technology, 3D-printed, 3D- printer service, Additive manufacturing technologies, 3systems, desktop 3D-printer