MSLattice is a design tool for Additively Manufactured Lattice Structures. This article reviews their Design, Performance and Applications.

By Dr. Oraib Al-Ketan

Additive manufacturing, or commonly known as 3D printing, is the process of fabricating a part layer by layer through adding material only where needed. This process allows us to easily fabricate parts with very complex structures and enhance their functionality. As such, providing freedom of design. It is a major step toward the fourth industrial revolution which revolves around the digital transformation of manufacturing/production. Today, several additive manufacturing techniques exist for different types of materials and length scales. Day after day, this technique is witnessing wide adoption and is becoming more and more cost effective and is competing with current conventional fabrication techniques.

Design Tools for Additive Manufacturing

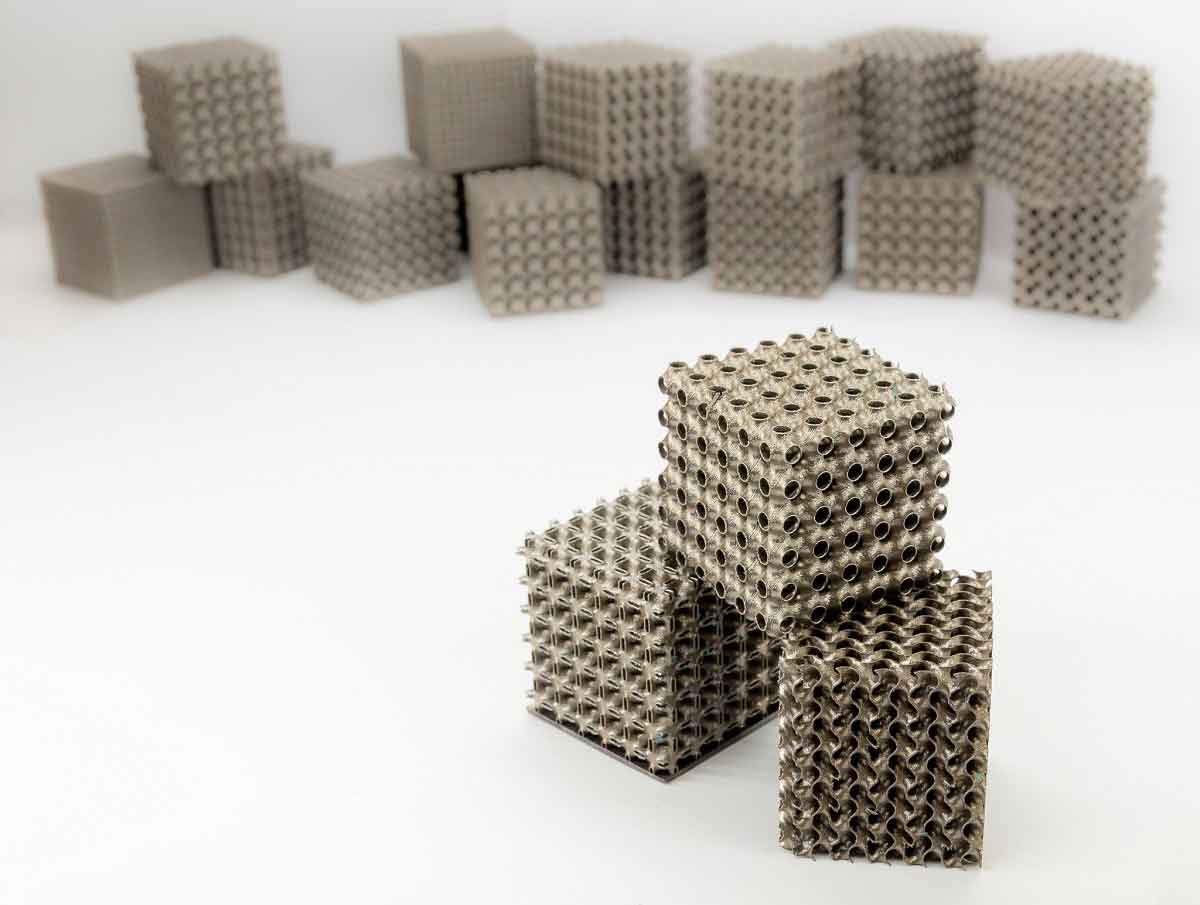

Despite the design freedom provided by additive manufacturing, the tools to create these designs are not easily accessible. Advanced CAD software are not reachable to most engineers. A fact that is hindering a wider adoption of such techniques by small businesses and start-ups. For example, designing lightweight components can be achieved by adding lattices to their structure. Lattices are materials with voids deliberately introduced in their bulk to reduce the weight and allow for fluid flow. These lattices enable custom-made designs with engineered properties through their topology-property relationship.

Additively Manufactured Lattice Structures

Recently, the Core technology Platforms at New York University Abu Dhabi in collaboration with the Advanced Digital and Additive Manufacturing Center at Khalifa University have developed a design tool that can be used to generate complex type of lattices that are generated using mathematical equations (Figure 1). These lattices are based on the well-known triply periodic minimal surfaces (TPMS) which have interesting characteristics such as large surface area to volume ratio and smooth curved shells that separate the space into interpenetrating domains (Figure 2). The Scientists and co-authors of this tool, Dr. Oraib Al-Ketan, and Dr. Rashid Abu Al-Rub refer to this design tool as MSLattice. It has been recently published in the journal Materials Design & Processing communication in a special issue “Additively Manufactured Lattice Structures: Design, Performance and Applications”.

MSLattice – Freely Accessible

By making MSLattice freely available for the research and engineering community, it is expected to have a wider adaption of TPMS-based lattices in different fields of engineering, said Dr. Al-Ketan. TPMS-based lattices can be deployed in various applications such as lightweight structures, support materials for 3D printing, thermal management devices (e.g., heat sinks, compact heat exchangers, phase-changing materials heat exchangers), scaffolds for tissue engineering, body implants, catalytic substrates, spacers, cores for sandwich panels, acoustic materials, photonic/phononic materials, electromagnetic shielding, and interpenetrating phase composites among other applications.

This user-friendly design tool is simple to use. Its user graphical interface (GUI) consists of four main tabs, namely; Uniform TPMS lattices, Functional TPMS grading, Implicit functions, and A simple STL viewer. The Functional TPMS grading tab contains two sub-tabs, namely; Relative density grading tab, and Cell size grading tab. In each tab the user can input a number of parameters such as cell type, cell topology, relative density, cell size, and sample dimensions, then the tool generate the 3D printing STL files required for experimental and computational investigations. The user can also change the relative density, cell size, or cell type in different direction to engineer the properties of the lattice (Figure 3).

Developers of the Vision

Dr. Al-Ketan hopes that MSLattice will expedite the employment of lattice materials in research areas that are not fully explored yet such as thermal management devices, interpenetrating phase composites, catalytic substrates, and waste water treatment to name a few.

The developers of MSLattice are currently working on further developing the tool to allow users to lattice arbitrary three-dimensional shapes such as 3D scans of bone and custom-made scaffolds for cell growth.

Related Keywords

, CAD/CAM, Computer aided design, Aided, Dimensional, Prototyping, Simulation, biomimetic, 3d-printing, Three-dimensional, Aerospace, Geometry, Prototypes, Additive, Computer aided, Aided design, Fabrication, Machining, Visualization, Modeling software, Additive manufacturing, Bio-inspired, Design software, CNC, 3d models, Cad software, Scanning, 3d modeling.

3d cad, Manufacturing processes, Polymer, Design process, Printers, Rapid-prototyping, Rendering, Parametric, 3d-printer, Prototype, Bionic, AutoCAD, SolidWorks, Geomtrical, Algorithms, Programming, product-development, geomtric, lightweight, drafting, light, optimization, production, fabrication, industry, visualize, simulation, geometric, cells, periodic, unit cell, design rules, thickness, walls, spacing, printable, reliability, feasible.