Agile Project Management in Refineries overhaul is the subject of this article. Here we talk about Agile methodology in overhaul Project Management of refineries and its application instead of traditional Waterfall method – A Case Study in Oil Refining Companies. First, we talk briefly about refineries and the state of implementation of overhaul projects in them. Then we will explain the necessity of using Agile Project Management in overhaul projects of refineries and describe its benefits.

By: Sohrab Askari (Associate Multidisciplinary Engineer at Cademix Institute of Technology, Austria)

Overhaul and Maintenance in Refineries

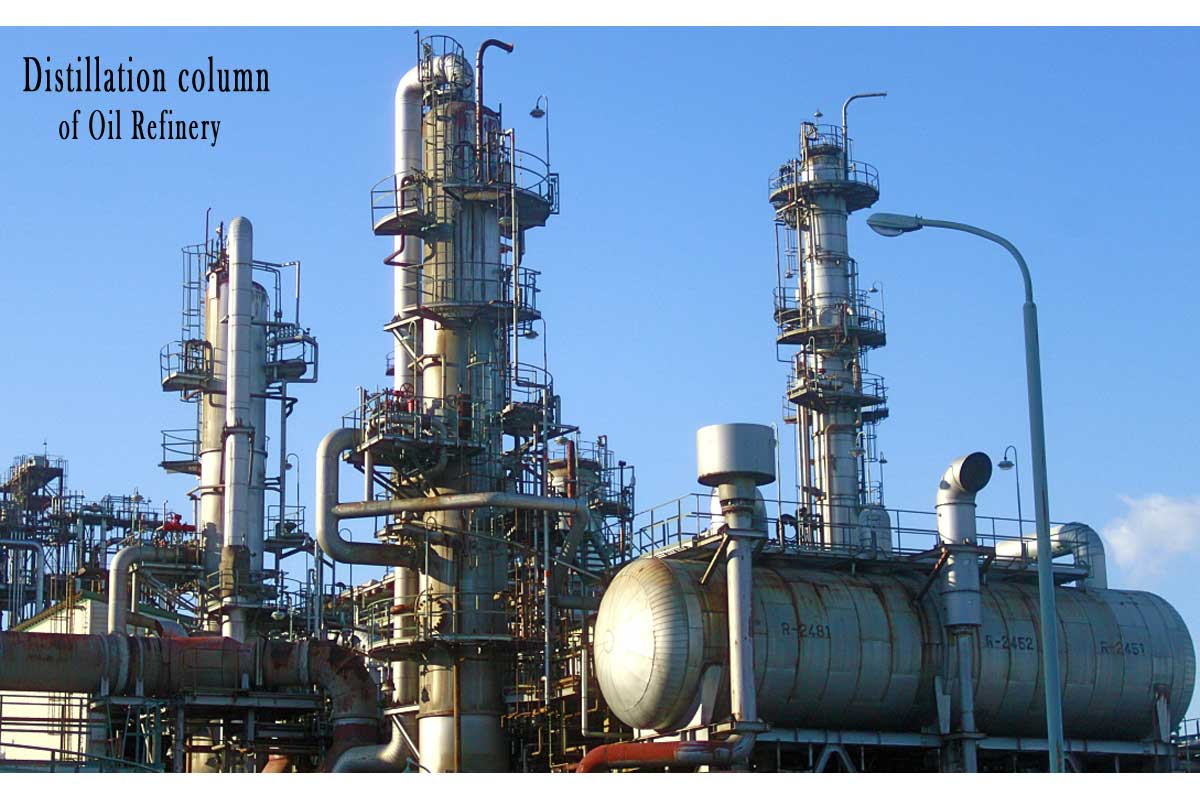

An oil refinery, also known as a petroleum refinery, is a manufacturing facility that converts crude oil into products including petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel, and fuel oils. An Overhaul is a frequently used word in the industry and especially in maintenance. By definition, an overhaul means a thorough checking and performing the required repairs or reparations of all machinery, equipment, and parts in an industrial unit. We use the term frequency in complex Industries including the oil production industry, aviation industry, ships and vessels, trains, airplanes, etc.

There are a large number of installations, equipment, and machinery in the refinery that are always working to refine the crude oil and produce petroleum products.

Overhaul in oil refining companies is a total checking of installations, machines, and equipment and doing needed repairs. For instance, it includes distillation columns, atmospheric towers, heat exchangers, pumps, compressors, vessels, tubes, and so on.

State of Overhaul Maintenance in Oil Refining Companies

State-of-the-art overhauls in Oil refining companies include a planned Shutdown. It provides a suitable condition for implementing a special maintenance project which lasts up to several weeks!

It is a comprehensive shutdown of the operational unit and extends to the whole process to check or repair all installations and machinery. This means, stopping all production processes in that unit. Subsequently, it will change the overall production plan of the refinery.

Production plans are very daily-variable in oil refineries; Overhaul project managers should use a suitable methodology to be able to make timely, fast, evaluated, and agile changes. It means that overhaul project needs a high level of agility to make more consistency with production plans.

What’s the Problem?

Currently, overhaul projects are managed by the Waterfall method in some companies. In most refineries (especially in Third-World countries), despite the agility of production projects, unfortunately, maintenance and overhaul projects are Waterfall types.

Waterfall Model methodology is a Liner Sequential Life Cycle Model. It followed in sequential order.

Agile methodology is a practice that helps continuous iteration of development of overhaul results and testing in the repairs process. In this model, development and testing activities are concurrent, against the Waterfall model. The Agile method allows more communication between Stakeholders, Overhaul team members, Overhaul managers, and product owner.

The problems seen in this method of overhaul can be discussed in two general areas:

1- Lack of Flexibility in the Waterfall Overhaul Project to Make Changes During Execution

The Overhaul project team only moves to the next phase of testing or repairing if the previous step is completed successfully because Waterfall is a linear and sequential approach.

2- Imposing more and newer Costs in case of Change in the Time of Major Repairs by Waterfall method :

Although there are several kinds of costs in each project, for instance, material supply and human salaries but the main cost is production reduction during the overhaul implementation. In order to decrease incurring final overhaul costs, we should use an appropriate project management method to make more coordinate with the production management plans.

Which Methodology in Refineries? (Waterfall or Agile?)

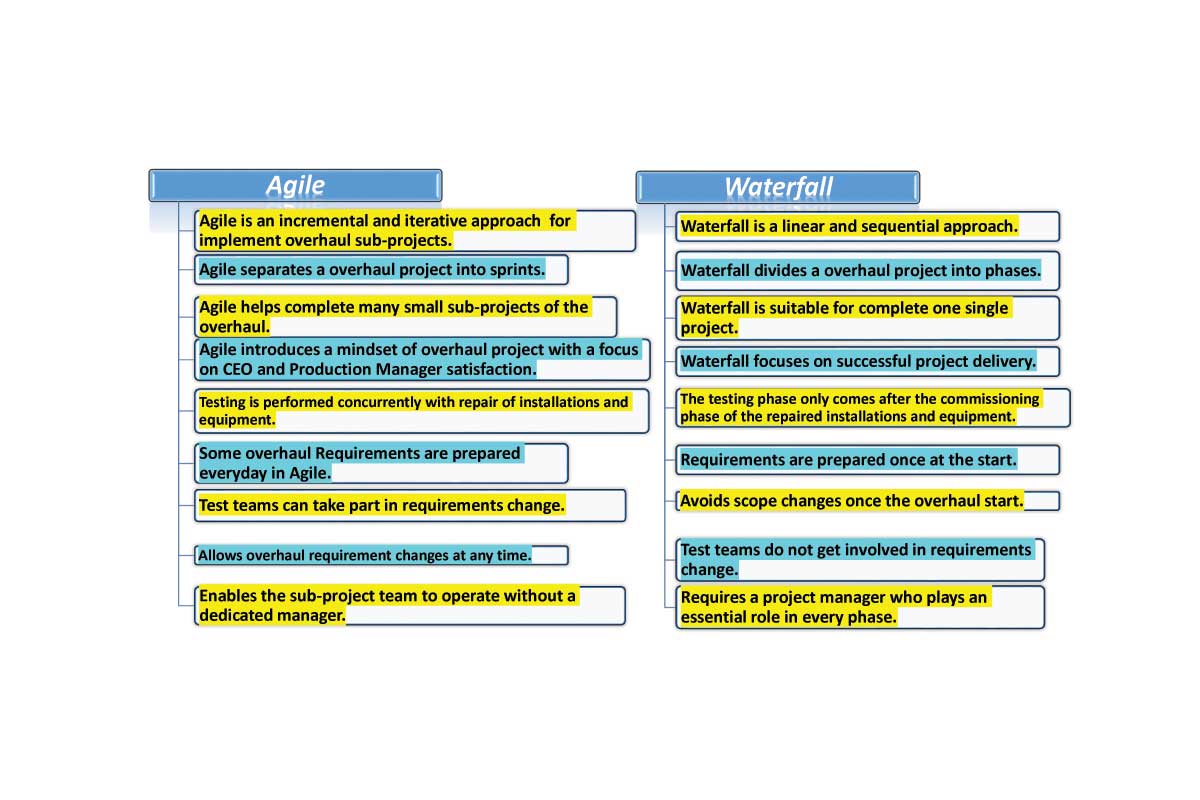

There are some advantages and disadvantages to using Waterfall or Agile methodology to implement the overhaul.

By Waterfall methodology, we can complete the overhaul project almost at the predicted time. There is Straightforward planning and designing due to the agreement on deliverables at the start of the overhaul project. Dedicated resources can work in parallel for their specific tasks. It also is more suitable for material supplying costs or human costs (because there are no additional costs related to iterative tasks or development). There are also clear measurements of progress. perhaps, it is better designed with a whole-system approach.

Currently, in most refineries (especially in Third-World countries), despite the agility of production projects, unfortunately, maintenance and overhaul projects are Waterfall type. Although overhaul projects in the oil industry require large budgets and the number of team members in each project is large, but it seems necessary to change the approach of projects from Waterfall to Agile Project Management.

Agile methodology has more flexibility to receive feedbacks and do repair improvements by iterative tasks. so, Agile Project Management in Refineries is an important step in this direction. Although it may increase the duration of some sub-projects or tasks there are some strategic reasons that can motivate project managers to implement the overhaul project by Agile methodology!

Why Agile Project Management in Refineries

Agile Project Management is more flexible than Waterfall. By an Agile method, the overhaul project can adjust with the unpredicted situations, for instance, ordered changes about the start date of project implementation or providing new requests during implementation.

Sometimes, Stakeholders (which here are the Product Operations Management team) or Product Owner (here, the Technical Inspection and Quality Control office) requests some fundamental changes; They also may order some additional requests during the tasks or sub-projects! In this situation, the Waterfall management method cannot make rapid changes or it may be very costly but the Agile methodology can do it.

In addition, sometimes for various reasons, the time of the overhaul project implementation may temporarily be canceled or postponed to the future due to Government orders! So, by Agile Project Management we can prevent increasing the high-risk costs (particularly about the goods and materials supply costs, warehousing costs).

Therefore, creating the maximum coordination between the overhaul planning and production plans highlights the need for the agility of overhaul projects. Agile methodology is needed to make the ability for adapting to unforeseen and instantaneous conditions.

Obviously, reducing the total cost of carrying out an overhaul project requires performing the project within an optimal range and it needs having good appropriateness and coordination with the production plans and company policies. There are some parameters that cause the production plans and company policies to be so daily variable. So, an agile overhaul can make a suitable adjustment with these variable situations. But, what are the parameters exactly?

Parameters which cause the Daily-Variable Situations:

As mentioned, there are some factors that cause the daily-variable situations in a refinery. The production plans change frequently due to their high dependence on these various parameters:

1-Orders Issued by the Government

General policies announced by the Government are one of the most important parameters that change production plans daily. The Government orders depend on some variables for instance:

- Volume of daily total petroleum producing in country.

- Country’s daily requirement for each product.

- Keeping a balance between the total daily volume Crude Oil extraction in the country and the daily consumption of crude oil by Refining companies.

- Maintaining the proportions set in crude oil exports and also export and import of petroleum products.

- General policies about storage capacity of crude oil and also petroleum products affected by forecasting the need in the coming months.

- caution in all estimations and calculations of production and consumption volumes of crude oil and petroleum products.

- Considering the different Geo-political situations in the regional-international dimension in the future.

2- Environmental Phenomena and Conditions

- Some environmental phenomenal such as air pollution in the region that leads to the need to reduce production processes in some industries- Refineries, for example.

- Seasonal condition of air temperature is also another environmental phenomenal element which affects the decisions. As the weather cools, the demand for petroleum products increases; With the arrival of the warm seasons, the demand for petroleum products decreases. The variability of demands directly affects the production and supply of petroleum products. So, this is another factor in the variability of production programs.

3-Routine and Daily Changes of some Operating Conditions in Refineries

- Daily variety of empty capacities in the storage tanks in the oil refineries and Oil Products Distribution Companies.

- Occurrence of some unforeseen conditions in case of failure of some key machines and equipment without replacement (pumps, compressors, etc.).

Agile Overhaul Implementation Steps

Using agile Overhaul to solve maintenance challenges in refineries will require organizations to rethink traditional ways of working and leverage new and enhanced management methodologies capabilities. In the author’s opinion, this process should incorporate six elements.

1- Integrated Dynamic Planning

By integrated dynamic planning, an overhaul project manager can use scenario analysis and plan manipulation to optimize sub-projects and tasks. He can do it based on the received datasets from the Product Management department of refinery and logistics constraints across the overhaul value chain and life cycle.

By only targeting critical areas for checking of installations, machines, and equipment and doing required repairs, much of the overhaul implementation can be consistent across a given field area. It can make results delivery execution more iterative and efficient as there are fewer changes occurring.

2- Data-Driven, Analytics-Led Design Optimization

Cognitive analytics and machine learning provide capabilities to more quickly identify variable factors -as mentioned- which most affect overhaul planning. Thus it helps avoid decreasing refinery products during the overhaul implementation -as the opportunity cost of developing repairs in overhaul- with optimal planning.

Overhaul planning team members should:

- Apply machine learning to optimized planning for smarter targeted management.

- Pushing the performance testing repaired machineries .

- Enabling more consistent aspects of overhaul planning in the agile project delivery approach.

3- Digitalization

Decluttering or eliminating manual and time-intensive processes can free up engineers and field leadership to focus on more value-added activities.

Digitizing workflows can enable process automation, create faster and easier links across tasks, and improve collaboration by bringing the right information to the right people at the right time. This combination can improve efficiency, ease scalability, and increase standardization across workflows.

4- Real-Time Drilling & Completion (D&C) Monitoring & Control

Using remote operation centers (ROC) to conduct real-time monitoring and control of D&C (for example, HSE principles training, industrial discipline, teamwork principles, new specialized repair skills, etc.). It helps workers to more rapidly learn before overhaul and also react throughout the overhaul results delivery process.

This institutionalized approach to real-time data and analytics can:

- Improve good execution and good results.

- Apply learning and experiences to the next overhaul in the refinery.

- Improve resource utilization and knowledge transfer to the future workforce.

5- Continuous and Automated Feedback Loop

Machine learning can help the project management team better determine the impact of good planning on a good performance during the early life of overhaul.

Digital facilities can also enable project controllers to :

- more quickly uncover key findings.

- Automate sharing with relevant engineers and stakeholders.

- Feed information back into an integrated, dynamic plan that maximizes good and field potential.

6- Integrated Overhaul Team & Refining Product Management Department Platforms

It’s time for the traditional interactional relationship between Refining Product Management and project management team members to evolve to meet the new realities of pace and scale in unconventional challenges.

As planning team members establish integrated data platforms that strengthen cross-functional collaboration, there is significant value potential in extending this to the workspace to create a more transparent and efficient operating model. This can make value creation a shared goal.

Benefits of Running the Agile Model in Overhaul:

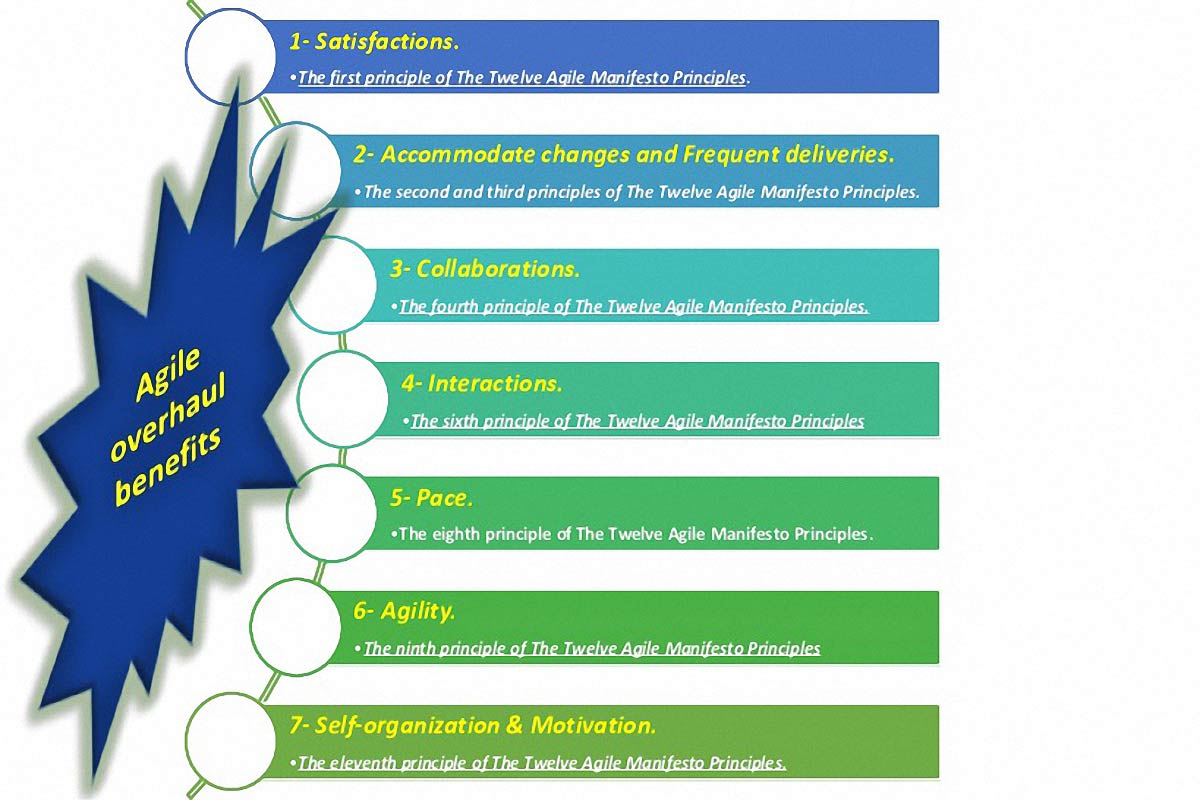

1- Satisfactions

The satisfaction of the Stakeholders and Product Owner:

Agile overhaul can satisfy Stakeholders (which here are the Product

Operations Management team) by accelerating the completion of the project and

the early delivery of the Production operational unit.

Also it can satisfy the Product Owner (which here is the Technical

Inspection and Quality Control office) through iterative and continuous

delivery execution results of sub-projects or tasks.

They are happier when they receive results at regular intervals than they

wait for a long time to complete the main project , while in Waterfall methods,

they have to wait until the end of the project and wait for the final whole

project results! (The first principle of The Twelve Agile Manifesto

Principles.)

2- Accommodate Changes and Frequent

Deliveries

Accommodate changing requirements and Frequent deliveries throughout the

development process (according to the request of the stakeholders):

The ability to avoid delays when a requirement or feature request changes;

While in the Waterfall method, there is no such flexibility during the

implementation phase of project and all sub-projects and tasks must be

performed exactly according to the predefined plans! (The second and

third principles of The Twelve Agile Manifesto Principles.)

3- Collaborations

The best Collaboration between the Overhaul Stakeholders and technical team

throughout the project:

Better decisions are made when the Stakeholders and technical team are

aligned. (The fourth principle of The Twelve Agile Manifesto Principles).

4- Interactions

Enable face-to-face interactions – Communication while in the Waterfall

method, such a feature is rarely possible! (The sixth principle of The

Twelve Agile Manifesto Principles.)

5- Pace

Supporting a consistent Technical and Maintenance pace :

Teams establish a repeatable and maintainable speed at which they can

deliver working repaired equipment and Machines, and they repeat it with each

release; again, in the Waterfall method, such a feature is rarely possible! (The

eighth principle of The Twelve Agile Manifesto Principles.)

6- Agility

Attention to details of right technical skills and good implementations:

It enhances agility and ensures the team can maintain the pace, constantly improve

the Results and sustain change. so, this is possible in a Agile Overhaul

project managing. (The ninth principle of The Twelve Agile Manifesto

Principles.)

7- Self-Organization & Motivation

Agile Maintenance implementation leads to making Self-organizing, Skilled

and motivated team members that encourage great planning, requirements, and

implementations:

So, regular communications with other team members and sharing ideas that

deliver quality results will take place unlike the waterfall method, which does

not give team members a chance at such opportunities! (The eleventh

principle of The Twelve Agile Manifesto Principles.)

8- Efficiently

Finally, receiving regular feedback and reflections will help team members

work more efficiently! (The twelfth principle of The Twelve Agile Manifesto

Principles.)

Conclusion

Agile Project Management is a new approach in overhaul of oil refinery

units. Overhaul project managers can use this method instead of Waterfall

method to reach some better results.

Overhaul implementation in an operational unit of refinery stops production

processes in that unit. Subsequently, it will change the overall production plan

of the refinery. so, the overhaul project should adjust with the production

plans. On the other hand, there are some factors which cause production plans

encounter with unpredictable situations and change frequently. So, Agile

Project Management has more flexibility than Waterfall to adjust with these

variable and unforeseen situations.

In addition, by Agile methodology changing requirements and frequent

deliveries throughout the development process are reachable. It also will make

more interactions and collaborations and team members will have more pace,

self-organization & motivation and it leads to increase efficiently.

Finally, all above results make reduction of total cost of carrying out the

overhaul project. You may get further details about the implementation and

career development in the area of agile project management at Cademix Institute of

Technology.

Keywords Related to Petroleum Oil Refineries

Major keyword related to agile project management in refineries are Refinery, Oil industry, Overhaul, Stakeholder, Product owner, fuel. Then, benzin, diesel, cracking, coking, and visbreaking processes, petrol, polymerication, fuel oils, gasoline, crude oil, vessel, ship, delivery, refineries, kerosene, supply, maintenance, Crude Oil , Kerosene , Gasoline, Gasoil, Fuel Oil, Oil Petroleum Refinery, Heat-Exchanger, Hydrocracking, Maintenance.

Other Keyphrases related to agile project management in refineries includes Refinery, Oil industry, Overhaul, fuel, benzin, diesel, cracking, coking, and visbreaking processes, petrol, polymerication, fuel oils, gasoline, crude oil, vessel, ship, delivery, refineries, kerosene, supply, maintenance, Crude Oil , Kerosene , Gasoline, Gasoil, Fuel Oil, Oil Petroleum Refinery, Heat-Exchanger, Hydrocracking, Maintenance Refinery, Oil industry, Overhaul, fuel, benzin, diesel, cracking, coking, and visbreaking processes, petrol, polymerication, fuel oils, gasoline. Further we can mention crude oil, vessel, ship, delivery, refineries, kerosene, supply, maintenance, Crude Oil, Petroleum industry, Gases, Boiling, Hydrogen-sulfide, Downstream, Residual, Sulfide, Refining industry, Fluid catalytic cracking, Oil-company, Oil companies, Isomerization, Sulfuric-acid, Sulfuric, Butane, Process safety.

Oil products, Sulphur, Tankers, Reformer, Impurities, Propane, Oil-gas, Refining process, Chevron, Shale, Residuum, Storage tanks, Refiners, Refining operations, Crude oil refining, Terminals, Exxonmobil, Wastewater, Natural gas processing.

About the Author

Sohrab Askari is an associate Multidisciplinary Engineer at Cademix Institute of Technology (Austria). He is also graduate with an MSc in Industrial Engineering and BS in Computer Engineering and as a Multidisciplinary skilled in Supply Chain Management (SCM), Project Management, several Computer Languages Programming, and mechatronics, has worked in a large refining company with a global reputation for several years (more than 15 years) in the field of Supply Chain Management (SCM) and Project Management of maintenance focused on Oil industries especially Oil refining companies.