3D printing-technology is advancing rapidly. It is also known as additive manufacturing and becoming popular with manufacturers. Automotive industry is growing fast using additive manufacturing. In this article we will show the role of 3d-printing technology in the mechanical engineering field specially in automotive industry.

Author Identification Code: CX8301574926, Cademix Institute of Technology

What is the 3D-printing?

Cars are manufactured from hundreds of elements. some of them can be tremendously complicated and hard to make.

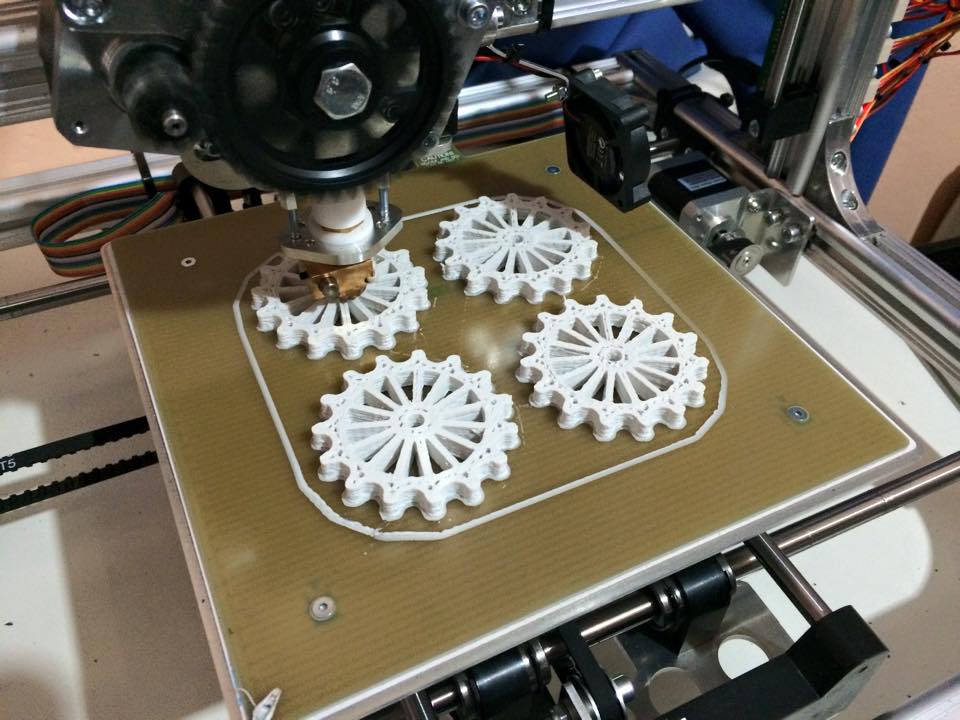

the advent of 3-D printers especially metallic based ones revealed that making vehicle elements on-demand, can be quick, accurate, and even can create lighter elements that use much less petrol. Three-dimensional (3D) printing is an additive manufacturing technology that turns a digital design into a physical object. The method involves spreading down thin layers of material, such as liquid or powdered plastic, metal, or cement, and then fusing them together. This technology has so many years of history which started from 1940s.

3D Printing Market

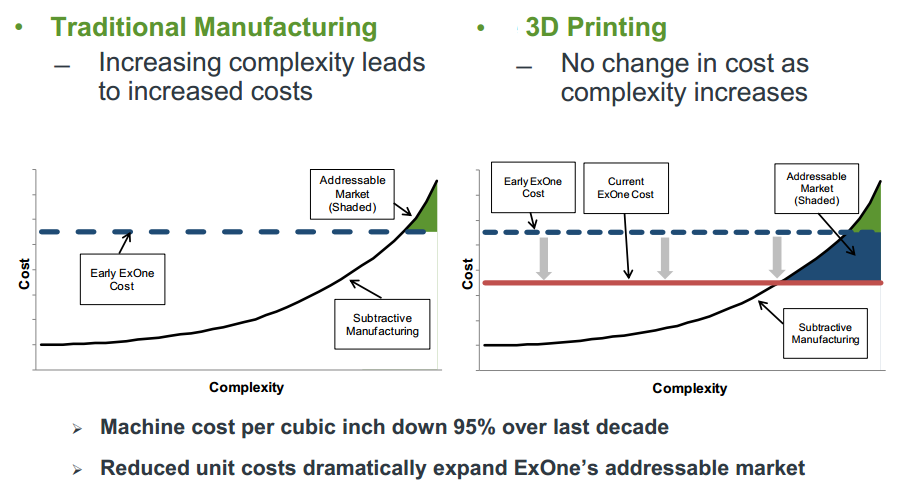

Three-dimensional printing makes it as cheap to create single items as it is to produce thousands and thus undermines economies of scale . It may have as profound an impact on the world as the coming of the factory did (…) Just as nobody could have predicted the impact of the steam engine in 1750 —or the printing press in 1450, or the transistor in 1950 —it is impossible to foresee the long-term impact of 3D printing. But the technology is coming, and it is likely to disrupt every field it touches..

— The Economist, in a February 10, 2011 leader

The global 3D printing market size is increased from USD 1.6 billion in 2020 to 4.5 billion by 2025. A CAGR (The compound annual growth rate) of 23.5% between 2020 and 2025. The 3D printing materials industry is growing at a global demand due to the needs of the health, automotive and other industries.

The materials request is expected to witness slower growth in 2020 due to COVID-19. But this reduction doesn’t last forever. at the end of lock-down and recovery in the industries show that the 3D printing materials’ demand starting to rise during the foredooming period. The field of 3D printing is a fascinating field that is developing new creative and engineering ways. This field is evolving rapidly and has reached many branches and mainstream users in the industry.

As you will see in the following paragraphs, 3D printing made a revolution in manufacturing process for every car company.

3d printing and industry

3D printers have changed the whole manufacturing process in the world. Nowadays, many companies have adopted this manufacturing technology.Here are some of the industries using 3d-printig Technology:

Drone/Aerospace & defense/ Robots/Automotive/Medical & dental / Food / Education etc.

Role of 3D-Printing Technology in the Automotive Industry

The automotive industry has been rapidly-advanced with additive manufacturing. High-profile companies like Audi using 3D printers. It is not just the Audi’s of the world that are using 3D printers. many automotive industries are using 3D printers in areas such as motorsports. The advantages of this technology than the old ones are greater design flexibility, customization, and faster product development. The real role comes when you pull back the curtain and see the production and testing processes. The most common parts printed by automotive manufacturers are fixtures, cradles, and prototypes, which need to be sturdy, stiff, and long-lasting. Moreover, 3D printing helps this industry to create complex geometric such as internal channels, fine mesh, and thin walls.

Which Automotive Companies are using 3D Printers?

By adopting 3d printing technology in car companies, we can realize that how this technology can stand out. The most credible and high-quality automotive manufacturers are using 3D printing. Here are some of the major companies using 3D printers:

- Audi/ BMW/Bugatti/Ford/Porsche/Volvo/GM/Rolls Royce

In the following section we can see few examples from top-notch automakers using additive manufacturing (3D printing).

The 5 Most Exciting 3D Printed Vehicles

1- LSEV by XEV & Polymaker

Italian electric vehicle company XEV and leading 3D printing company Polymaker have developed the world’s first mass-produced 3D printing car.

2- The Blade by Divergent Technologies

The world’s first 3D-printed super car is called Blade which is from manufacturer Divergent Technologies.

3- The Light Cocoon

In 2015, the Light Cocoon car combines 3D printing and ecological materials was First shown at the Geneva Motor.

4-The Light Rider

This electrical motorcycle designed by APWorks, a subset of the Airbus group.

5-McLaren 720S

British sports car maker McLaren has used 3D printing technology for man products.

3D printing in the automotive industry: Advantages

There are so many Advantages and Disadvantages for this technology. Here, we will mention the Pros list :

Fast Prototyping, Design and Production / Flexible in Designing / Minimizing Waste, Time and Cost / Print on Demand/ Strong and Lightweight instead of Heavy Parts/ Environmentally Friendly /Advanced Healthcare. As a one-step manufacturing process, 3D printing saves time and money. it eliminates different machines for manufacturing. You can even set up a 3D printer, eliminating the need for an operator to be present at all times.

What are the Disadvantages of 3D printing?

Reduction in Manufacturing Jobs / Limitation in Materials / Restricted Build Size / Post Processing Problems / Design Inaccuracies / Copyright Matters